Electric motors are the unseen workhorses of our modern world, powering everything from the smallest household gadgets to the largest industrial machinery. Yet, beneath their seemingly simple function lies a complex interplay of electrical principles. Understanding wattage, and the fundamental distinctions between Direct Current (DC) and Alternating Current (AC) motors, is crucial for selecting the right motor for any task. This comprehensive guide will demystify these concepts, empowering you to make informed decisions for optimal performance and efficiency.

What is Wattage and Why Does it Matter for Motors?

Wattage is a fundamental measure of electrical power, representing the rate at which electrical energy is converted into another form, such as mechanical energy in a motor. Importantly, a watt remains a watt, whether it refers to an AC or DC system. For instance, 100 watts of power is the same quantity of power regardless of the current type. This power rating indicates how much work a motor can perform or how much energy it consumes.

The relationship between power (watts), voltage (volts), and current (amperes) is crucial: Power (Watts) = Voltage (Volts) × Current (Amps). This means that for a given wattage, if the voltage is lower, the current (amperage) will be higher, and vice-versa. For motors, wattage directly relates to the motor’s output capability and its potential energy consumption. A higher wattage typically suggests a motor designed for more demanding tasks, but it’s not the sole indicator of performance; efficiency also plays a significant role in how effectively that wattage is converted into useful mechanical work.

Understanding DC Motors: Advantages and Disadvantages

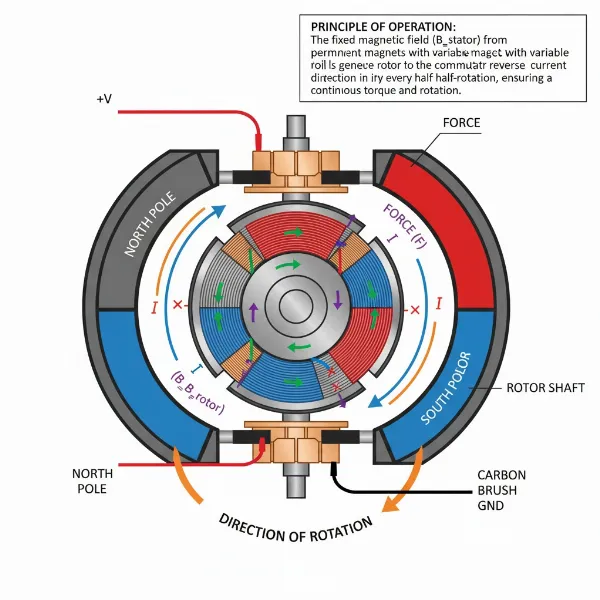

Direct Current (DC) motors operate using a power source where electricity flows in a single, constant direction, much like the current provided by batteries, solar cells, or rectified power supplies. Their operation relies on the interaction between a fixed magnetic field, generated by permanent magnets or electromagnets, and a variable magnetic field created by an electric current flowing through a coil in the rotor (the rotating part).

There are several types of DC motors, including permanent magnet, series, shunt, and compound motors, each with specific characteristics. A key distinction is between brushed and brushless DC motors. Brushed DC motors, one of the oldest motor types, use carbon brushes and a commutator to reverse the current in the rotor, allowing continuous rotation. Brushless DC (BLDC) motors, on the other hand, eliminate these wear-prone components by moving the permanent magnets to the rotor and using electronically switched electromagnets in the stator, leading to greater longevity and efficiency.

Diagram illustrating the internal components of a brushed DC motor, including rotor, stator, brushes, and commutator.

Diagram illustrating the internal components of a brushed DC motor, including rotor, stator, brushes, and commutator.

Advantages of DC Motors:

- Precise Speed and Torque Control: DC motors excel in applications requiring fine control over speed and torque. By simply adjusting the applied voltage or current, their speed can be easily and accurately varied.

- High Torque at Low Speeds: Many DC motor designs offer substantial torque even at low rotational speeds, making them ideal for tasks requiring strong initial force.

- Responsiveness: They are highly responsive to changes in control inputs, providing quick acceleration and deceleration.

|

Our Picks for the Best Hand mixer in 2026

As an Amazon Associate I earn from qualifying purchases.

|

||

| Num | Product | Action |

|---|---|---|

| 1 | OVENTE 5-Speed Corded Electric Hand Mixer with Stainless Steel Whisks, Compact Portable Design with Snap-On Storage Case,150W Lightweight Handheld Mixer for Baking & Cooking, White HM151W |

|

| 2 | Hamilton Beach 6-Speed Electric Hand Mixer with Whisk, Traditional Beaters, Snap-On Storage Case, 250 Watts, White |

|

| 3 | OVENTE 5-Speed Electric Hand Mixer with Stainless Steel Mixing Whisk, Snap-On Storage Case, Portable & Lightweight 150W Motor, Compact Handheld Mixer for Baking, Blending or Cooking, Red HM151R |

|

| 4 | KitchenAid 5-Speed Ultra Power Hand Mixer - KHM512, Contour Silver |

|

| 5 | KitchenAid 5 Ultra Power Speed Hand Mixer - KHM512, Aqua Sky |

|

| 6 | 600W Electric Hand Mixer Kitchen Handheld Mixer 10 Speed Powerful with Turbo for Baking Cake Lightweight & Personal Electric Mixer with Egg Baking Beaters Dough Hooks, Whipping Mixing Cookies |

|

| 7 | OVENTE 5-Speed Corded Electric Hand Mixer with Stainless Steel Whisks, Compact Portable Design with Snap-On Storage Case,150W Lightweight Handheld Mixer for Baking & Cooking, Black HM151B |

|

| 8 | Wellness Extract Multi-Speed Rechargeable Electric Milk Frother, Li-ion Battery Powered – Certified Safe, Ideal for Coffee, Matcha, Protein & Colostrum |

|

| 9 | KitchenAid 5-Speed Ultra Power Hand Mixer |

|

| 10 | Maestri House Rechargeable Milk Frother with Stand, LunaFro Handheld Electric Foam Maker Waterproof Detachable Stainless Steel Whisk Drink Mixer Foamer for Lattes, Cappuccino |

|

Disadvantages of DC Motors:

- Complex Construction (Brushed Types): Brushed DC motors have a more intricate design due to the need for commutators and brushes, which are essential for reversing current in the rotor.

- Higher Maintenance (Brushed Types): The brushes and commutators in brushed DC motors are subject to wear and tear from friction, necessitating regular maintenance and eventual replacement. This can lead to a shorter lifespan compared to AC motors or brushless DC motors.

- Cost: Due to their more complex construction and sometimes specialized control systems, DC motors, particularly brushless ones, can be more expensive to manufacture than their AC counterparts.

- Sensitive to Load Changes: Brushed DC motors can be sensitive to fluctuations in load, which might affect their speed stability without proper control mechanisms.

Applications of DC Motors:

DC motors are frequently found in applications where precise control and compact power are paramount. These include:

- Electric Vehicles and Robotics: Their excellent speed and torque control are crucial for movement and manipulation.

- Power Tools: Portable drills, screwdrivers, and saws often use DC motors for their ability to operate on batteries and offer precise control.

- Medical Equipment: Devices like pumps and ventilators rely on DC motors for accurate and controlled operation.

- Toys and Portable Electronic Devices: Small DC motors are common due to their simplicity and battery compatibility.

- Positioning Systems: Used in printers and CNC machine tools where exact positioning is critical.

Understanding AC Motors: Advantages and Disadvantages

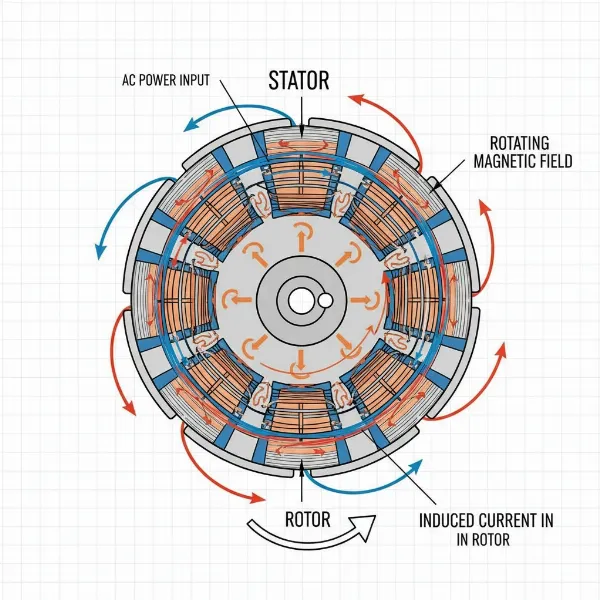

Alternating Current (AC) motors operate on alternating current, which is characterized by its periodic reversal of direction. This is the type of electricity supplied through the power grid to homes and businesses. AC motors convert electrical energy into mechanical energy by using a rotating magnetic field, which is generated by the alternating current in the stator (the stationary part of the motor). This magnetic field then interacts with the rotor, inducing a current and creating rotational motion.

The two main categories of AC motors are asynchronous (or induction) motors and synchronous motors. Induction motors, particularly the squirrel-cage type, are the most common due to their robust and simple design. Synchronous motors, on the other hand, rotate at the same speed as the supply current’s frequency, making them suitable for applications requiring perfectly constant speed.

Illustration demonstrating the principle of a rotating magnetic field in an AC induction motor's stator.

Illustration demonstrating the principle of a rotating magnetic field in an AC induction motor's stator.

Advantages of AC Motors:

- Simpler Construction: AC motors generally have a simpler and more robust construction because they do not require brushes or commutators (in induction types) to operate. This often translates to higher reliability.

- Lower Maintenance: With fewer wearing parts like brushes, AC motors typically require less maintenance, especially induction motors. This leads to reduced downtime and operating costs.

- Cost-Effective: AC motors are often more economical to manufacture and maintain, especially given their widespread use which benefits from economies of scale.

- Direct Grid Operation: They are well-suited to operate directly from the standard electrical grid without needing an external converter, simplifying power supply.

- Ideal for Constant Speed & Heavy Loads: AC induction motors are ubiquitous in heavy-duty, continuous-speed industrial applications where the motor speed is slow to medium and remains constant while the load on the motor may vary.

Disadvantages of AC Motors:

- Complex Speed Control: Unlike DC motors, precisely controlling the speed of AC motors is inherently more complex. It typically requires sophisticated electronic devices like Variable Frequency Drives (VFDs) to alter the frequency of the supply current.

- Efficiency Considerations: While modern AC motors are highly efficient, some designs can experience phenomena like “slip” (the difference between rotor speed and the stator’s magnetic field speed), which contributes to heat-related power losses. AC motors also use electromagnets in the stator, which consume electricity, whereas some DC motors can use permanent magnets, potentially offering higher efficiency in certain configurations.

Applications of AC Motors:

AC motors are favored in many industrial and domestic settings for their reliability and cost-effectiveness:

- Industrial Machinery: Widely used in pumps, fans, compressors, machine tools, and conveyor belts due to their robustness and low maintenance.

- Household Appliances: Refrigerators, washing machines, dishwashers, and air conditioners commonly feature AC motors for their reliable and efficient operation.

- Ventilation and Heating Systems: HVAC systems utilize AC motors for powering fans and circulating pumps.

- High-Power Applications: Traction motors for trains, elevators, and other applications requiring significant, reliable power often use AC motors.

DC vs. AC Motors: A Detailed Comparison

Choosing between a DC and AC motor often comes down to balancing specific application requirements with their inherent characteristics. Here’s a comparative overview:

| Feature | DC Motors | AC Motors |

|---|---|---|

| Power Source | Direct Current (DC) from batteries, solar cells, rectified power supplies. | Alternating Current (AC) from the electrical grid. |

| Speed Control | Easy and precise control by adjusting voltage/current. | More complex, typically requires Variable Frequency Drives (VFDs). |

| Construction | More complex (brushed types due to commutators/brushes). | Generally simpler and more robust (especially induction types). |

| Maintenance | Higher (brushed types due to brush/commutator wear). | Lower (fewer wearing parts, especially induction/brushless). |

| Cost | Often more expensive to manufacture (especially complex types). | Generally less expensive to manufacture and maintain due to widespread use. |

| Efficiency | Can be very efficient; brushless types excel. Brushed types have losses. | Can be highly efficient; modern induction motors offer excellent energy efficiency. |

| Typical Apps | Electric vehicles, power tools, medical devices, robotics. | Industrial machinery, household appliances, HVAC, pumps, fans. |

Factors to Consider When Choosing Between DC and AC Motors

Making the right motor choice extends beyond just understanding the basic differences; it involves a holistic evaluation of your specific operational needs.

- Power Source Availability: Your primary consideration should be the type of power readily available. If your application is battery-powered or requires portability, a DC motor is often the natural choice. Conversely, if connection to the electrical grid is constant and preferred, AC motors are typically more straightforward.

- Speed Control Requirements: For applications demanding precise, variable speed, or high torque at low speeds (e.g., robotics, precision manufacturing), DC motors offer superior control. If your application needs constant speed with less frequent adjustments (e.g., pumps, fans), AC motors, possibly with VFDs for flexibility, are well-suited.

- Maintenance Budget and Frequency: Consider the long-term maintenance implications. Brushed DC motors require periodic brush and commutator inspection and replacement, incurring higher maintenance costs and potential downtime. AC induction motors and brushless DC motors are known for their lower maintenance needs.

- Cost Implications: Evaluate both the initial purchase price and the total cost of ownership (TCO). While DC motors might sometimes have a higher upfront cost due to their complexity, their precise control can lead to operational efficiencies. AC motors, particularly standard induction types, often benefit from economies of scale, making them more affordable initially.

- Application Environment: The operating environment can influence motor choice. AC motors are generally more robust and tolerant of harsh industrial conditions. Brushless DC motors also offer good durability. Consider factors like dust, humidity, and temperature.

- Torque Characteristics: Does your application need high starting torque, or consistent torque across a broad speed range? DC motors can deliver consistent torque over their speed range, while AC induction motors often have excellent starting torque for heavy loads.

- Overall System Efficiency: Look at the entire system’s efficiency, not just the motor in isolation. While one motor type might be inherently more efficient in certain scenarios, the efficiency of power conversion (AC to DC or vice-versa) and the control system also contribute to the overall energy consumption.

Common Applications: Where You’ll Find Each Motor Type

The widespread adoption of both DC and AC motors highlights their unique strengths tailored to diverse needs.

DC Motors are the preferred choice for applications demanding portability, precise control, or operation from a battery source. You’ll find them powering:

- Electric Vehicles: From golf carts to modern EVs, DC motors, particularly brushless types, provide the necessary torque and speed control for propulsion.

- Portable Power Tools: Drills, saws, and screwdrivers leverage DC motors for their battery compatibility and responsive power delivery.

- Medical Equipment: Devices like insulin pumps, ventilators, and surgical tools often use miniature DC motors for their accuracy and reliability in critical functions.

- Robotics: The precise speed and torque control of DC motors are indispensable for robotic arms and mobile platforms.

- Consumer Electronics: Many small household gadgets and toys rely on compact DC motors.

AC Motors, renowned for their robustness and efficiency when connected to the grid, are ubiquitous in larger, continuous-operation settings:

- Industrial Machinery: They drive the vast majority of factory equipment, including conveyors, pumps, fans, and compressors, where constant, reliable power is essential.

- Major Household Appliances: Washing machines, refrigerators, dishwashers, and air conditioners typically use AC motors for their durability and efficiency in prolonged use.

- HVAC Systems: Large blowers and circulating pumps in heating, ventilation, and air conditioning systems are generally powered by AC motors.

- Water Pumps and Elevators: Applications requiring sustained, high-power output over long periods frequently employ AC motors.

Myth Busting: Common Misconceptions About Motor Wattage and Type

The world of motors is rife with assumptions. Let’s debunk a few common myths:

- “Higher wattage always means better performance.” Not necessarily. While higher wattage indicates a motor can handle more power, it doesn’t automatically equate to superior performance for every task. Efficiency is key; a lower-wattage, highly efficient motor might outperform a higher-wattage, less efficient one in specific applications by converting more of its input power into useful mechanical output. The optimal wattage depends entirely on the required task and load.

- “DC motors are always less powerful than AC motors.” This is a misconception. The power output of an electric motor, whether AC or DC, is primarily determined by its specific design, size, and the quality of materials used, rather than the type of current it runs on. Both AC and DC motors can be engineered to deliver similar power levels. For instance, large industrial DC motors exist, just as small AC motors do. The choice often comes down to how that power is delivered and controlled.

- “Converting AC to DC or vice-versa is 100% efficient.” Unfortunately, no electrical conversion process is perfectly efficient. When you convert AC to DC (rectification) or DC to AC (inversion), some energy is always lost, primarily as heat. These inefficiencies must be factored into the overall system design and power budget.

Expert Advice: Making the Right Motor Choice

Choosing the ideal motor for your application requires careful consideration and, often, expert input. “In summary, neither DC vs AC motors are inherently more powerful. Power depends on the specific design of the motor and the application for which it is used.” This statement from Crouzet underscores that there’s no one-size-fits-all answer.

An expert technician, like one from handmixerguide.com with years of experience, emphasizes the importance of prioritizing your application’s unique needs. Don’t fall for generic advice; instead, evaluate factors such as required speed and torque range, operational environment, expected lifespan, and the criticality of maintenance. Furthermore, always consider the total cost of ownership (TCO), which includes not just the purchase price but also energy consumption, maintenance, and potential downtime over the motor’s lifespan. Consulting with motor specialists or experienced electrical engineers can provide invaluable insights tailored to your project.

Buying Guide: Your Comprehensive Checklist

When you’re ready to select a motor, use this checklist to ensure you cover all critical considerations:

- Identify Your Power Source: Will the motor run on batteries, a low-voltage DC supply, or directly from the electrical grid?

- Determine Speed and Torque Control Needs: Do you need highly precise, variable speed, or is a constant speed acceptable? How much starting torque is required?

- Assess Maintenance Expectations: Are you equipped for regular maintenance of brushes, or do you require a lower-maintenance solution?

- Calculate Total Cost of Ownership: Look beyond the initial price tag to consider energy costs, maintenance, and expected lifespan.

- Review Application-Specific Requirements: Consider the operating environment (temperature, dust, moisture), duty cycle, and any specific regulatory standards.

- Check for Specialized Features and Accessories: Does your application require integrated gearboxes, brakes, or advanced control electronics?

- Consider Brand Reputation and Support: Choose manufacturers known for quality, reliability, and excellent customer service and technical support.

Conclusion

Understanding the intricacies of wattage and the fundamental differences between DC and AC motors is not merely an academic exercise; it’s a critical skill for optimizing performance, efficiency, and longevity across countless applications. While DC motors offer unparalleled precision and control, particularly from portable power sources, AC motors stand out for their robust simplicity and cost-effectiveness in grid-powered, constant-speed applications. There is no single “best” motor type; the optimal choice is always the one that most perfectly aligns with your specific operational needs and constraints. By carefully evaluating your requirements and applying the insights shared, you can make an informed decision that ensures your system performs reliably and efficiently for years to come.

What essential device in your daily life relies on a motor, and have you ever wondered if it’s powered by AC or DC?

Frequently Asked Questions

Is higher wattage always better for a motor?

No, higher wattage indicates a motor can handle more power, but “better” depends on the application. An efficient motor converts more wattage into useful work, meaning a lower-wattage, high-efficiency motor can sometimes outperform a higher-wattage, less efficient one for a given task. It’s about matching power to demand efficiently.

Are DC motors more energy efficient than AC motors?

The efficiency of both DC and AC motors varies greatly by design, size, and application. Brushless DC motors are often lauded for high efficiency. Modern AC induction motors also offer excellent energy efficiency. Factors like conversion losses (AC to DC or vice-versa) and motor load also significantly impact overall system efficiency.

Can I convert an AC motor to run on DC, or vice versa?

Directly converting an AC motor to run on DC, or a DC motor to run on AC, is generally not feasible without significant modifications that would essentially create a different type of motor. However, power can be converted (e.g., AC to DC using a rectifier, or DC to AC using an inverter) to supply the appropriate current type to the motor. This conversion process always involves some energy loss.

What’s the difference between brushed and brushless DC motors?

Brushed DC motors use physical carbon brushes and a commutator to reverse current in the rotor, leading to wear and requiring maintenance. Brushless DC (BLDC) motors eliminate these parts by using electronic commutation and permanent magnets on the rotor, resulting in higher efficiency, longer lifespan, quieter operation, and less maintenance.

Why are AC motors more common in industrial settings?

AC motors, particularly induction motors, are prevalent in industrial settings due to their simple, robust construction, which translates to high reliability and low maintenance requirements. They are also economical to manufacture and operate efficiently with the alternating current readily available from the electrical grid, making them ideal for continuous, heavy-duty applications.